|

Production Machining...

A complete tool kit to program any part on

any lathe.

ESPRIT delivers production quality G-Code programs

for turning that are highly optimized to minimize cycle times and tool

wear while maximizing part quality. Starting with a complete definition of

the cutting tools and comprehensive / flexible machining cycles, tool path

is quickly built from any 2D or 3D geometry, Solids or Surfaces model to

accommodate any cutting requirements. Built-in simulation and post

processing round out a complete tool kits for programming any part on a

lathe.

|

|

- 2-axis turning

- C- and Y-axis mill-turn

- multi-spindle / multi-turret turning

- "Swiss" style machine support

|

|

C and Y axis Mill-Turn...

Combining turning and milling operations

into one G-Code program.

You can combine turning and milling machining

operations in one G-code program with ESPRIT's support of both "C" and "Y"

mill-turn. Choose from milling contour - profile cutting, pocketing, or a

variety of drilling machining cycles. Perform 2 1/2-axis milling

operations on your lathe using its ZXC or ZXY axes. ESPRIT also provides

the tools to perform "Wrap" operations. The X-axis movement is converted

into a rotary C-axis movement, effectively "wrapping" your shapes

(pockets, holes, and contours) around the rotary axis. This makes ESPRIT

an excellent tool for slotting and cross drilling.

|

|

- C 3-axis and Y 4-axis mill-turn with power

tooling

|

|

Tooling...

ANSI / ISO standard coding for turning

tools, inserts and holders.

ESPRIT's tooling system supports it all, from

standard boring bars to complex custom form tools. The tooling library

uses ANSI/ISO standard coding for regular turning tools, both inserts and

holders, to simplify the process of defining your tooling. During the

creation of the machining cycle and simulation process the definition of

the complete tool (insert, holder, and turret) is used to insure your

confidence and a highly accurate result. Your custom tools can be drawn in

any CAD system, or in ESPRIT, and imported into the tooling library. While

using the ESPRIT SolidTurn Advanced, mill-turn option, the complete

library of milling cutting tools is also available.

|

|

- Library of standard inserts - ANSI and ISO

standard inserts for grooving, threading (top notch and lay down), and

turning including square, round, trigon, and diamond

- Library of standard holders - ANSI and ISO

standard holders with 25 turning and boring styles

- Unlimited custom tools and holders with

any geometry C 3-axis and Y 4-axis mill-turn with power tooling

|

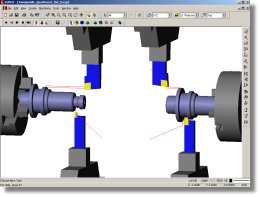

From

2-axis to 22-axis, ESPRIT is packed with

power to handle the most complex, multi-function mill-turn machines, while

easy enough to quickly program even the simplest turning job. Turning

machines and "Swiss" style lathes with the most complex tooling, turret, and

spindle configurations are easily programmed to perform turning, C-axis and

Y-axis milling with complete synchronization, post processing and machine

simulation.

From

2-axis to 22-axis, ESPRIT is packed with

power to handle the most complex, multi-function mill-turn machines, while

easy enough to quickly program even the simplest turning job. Turning

machines and "Swiss" style lathes with the most complex tooling, turret, and

spindle configurations are easily programmed to perform turning, C-axis and

Y-axis milling with complete synchronization, post processing and machine

simulation.