ESPRIT

SolidMillTurn is a comprehensive CAM system specifically designed for

programming parts for multi-function lathes and mill-turn machines.

SolidMillTurn features an extensive suite of

machining cycles for 2-5 axis milling, including full simultaneous 3-axis

and 5-axis 3D multi-surface/solid machining. SolidMillTurn provides the

freedom to use milling and turning cutting cycles in any combination and

provides control over the Z, X, “C”, “Y”, and “B” axes common to these

machine tools.

ESPRIT

SolidMillTurn is a comprehensive CAM system specifically designed for

programming parts for multi-function lathes and mill-turn machines.

SolidMillTurn features an extensive suite of

machining cycles for 2-5 axis milling, including full simultaneous 3-axis

and 5-axis 3D multi-surface/solid machining. SolidMillTurn provides the

freedom to use milling and turning cutting cycles in any combination and

provides control over the Z, X, “C”, “Y”, and “B” axes common to these

machine tools."B"-axis Programming...

Easily program

multi-axis tool movements.

Get the power and flexibility to perform 5-axis simultaneous multi-surface/solid milling and 5-axis index milling on your mill-turn machine tool. ESPRIT’s full 5-axis control lets you easily program parts demanding compound angles or non-perpendicular multi-axis tool movements, such as those required for tool holders, oil drilling tools, complex valves, and gear products. The 5-axis control is available for ESPRIT’s Advanced and FreeForm machining cycles including Facing, Contouring, Pocketing, Hole Making, 3D Finishing and more.

- Full 5-axis control for programming compound angles or non -perpendicular multi-axis tool movements.

"C" & "Y"-axis Machining...

Five levels of

functionality ....

ESPRIT SolidMillTurn is offered in five levels of functionality which provide support for the widest variety of parts and machine tools. “C”-axis rotary milling offers Wrap Pocketing, Contouring and Drilling for use on the Face or OD of your parts. For off-center, ”Y”-axis milling, ESPRIT features an extensive set of milling cycles including Facing, Pocketing, Contouring, Rest Machining, Hole Making and more. All of these machining cycles are available for use with “C”, “Y” and “B” axis for working on a part at compound angles, or on the Face, ID or OD.

- Five levels of functionality include Traditional, Advanced, Production, FreeForm and FreeForm 5-axis

Synchronized Milling and

Turning ...

Integrated programming

environment for milling and turning together.

Use ESPRIT SolidMillTurn in conjunction with ESPRIT SolidTurn to program any combination of mill-turn (2-5 axis) and turning cutting cycles, using one or more spindles with multiple turrets (up to 22-axis), in one session complete with synchronization, optimization and solid simulation. ESPRIT is the one CAM system that provides a completely integrated programming environment for milling and turning together, at one time, on one machine tool.

- A comprehensive solution for programming any combination of 2-5 axis milling and turning cutting cycles, including full programming support for 4th and 5th axis ("C" and "B" axis).

KnowledgeBase™

Automatically recognize

and analyze part features, and more ...!

The array of knowledge base tools in ESPRIT enables you to automatically recognize and analyze part features (Feature Recognition), and easily create, store, and re-use machining processes (Process Manager). In addition, you can easily synchronize and optimize machining cycles through a combined display of cutting operations and cycle times (Sync List). ESPRIT then dry-runs simulations of the resulting machining processes in dynamic 3D images that show the whole part on screen, including each spindle and turret, and the cutting tools. ESPRIT also includes a comprehensive feeds, speeds and material database and an ANSI/ISO coded tooling library, providing users with optimum feedrates and tools for machining parts.

- Create, store and re-use machining processes with the Process Manager

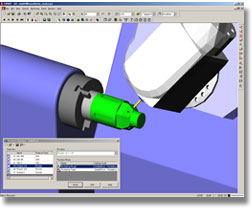

Simulation and

Verification...

Assures your NC programs

are of the highest quality.

The Solid Simulation and Verification tool allows you to quickly and easily dry run your programs on the computer to verify accuracy, and assures your CNC programs are of the highest quality, all before ever cutting a chip. The entire machining environment including spindle(s), turret(s), B-axis heads, and all your tooling is clearly represented in dynamic 3D solid images. Meanwhile, all the machine’s movements, including sliding head stock, are accurately represented to promote complete confidence in the quality of your G-code program.

- View the entire machining environment in 3D solid images