|

Feature Based Machining...

Automatic programming without sacrificing

tool control.

Whether you are machining solids, surfaces, 3D

models or 2D drawings you are machining a work piece to produce a part.

That part is composed of physical features such as: holes, pockets, slots,

etc. ESPRIT’s Feature Based Machining uses this concept of part features

to ease the programming process.

ESPRIT’s Feature Recognition automatically

recognizes a part’s features and its properties such as height, depth, and

work plane orientation. When each feature is machined, the tool path is

created using these properties eliminating the need to manually enter

cutting parameters. The parameters are automatically set based upon the

feature you are machining. You’ll benefit from completely automated

programming without sacrificing tool control when you need it.

|

|

- Feature Based Machining from any solid,

surface, 3D wire frame model or 2D drawing automatically recognizing

depth, thickness, holes, pockets, slots, profiles, etc.

|

|

KBM Project Manager...

To easily organize your work.

An essential tool to easily organize your work, the

Project Manager helps you sort out what you are cutting, how you’re

cutting it, and which cutting tools you are using.

Within the “Feature Tab” your work piece is divided

into machinable features such as holes, slots, and pockets. For each

feature you’ll have a list of cutting operations. Add, change, or remove

any machining cycle at any time.

An “Operation Tab” provides a sequential list of

cutting operations as they appear in the G-code. Organize and optimize

your program using simple Windowsâ drag and drop techniques. The “Tool

Tab” manages your cutting tools, and provides access to your tooling

libraries.

|

| |

- Project Manager to organize your work with

Feature tab, Operation tab, and Tool tab

|

|

KBM Property Browser...

For control over all the machining

conditions.

The Property Browser gives you

control over all the machining conditions. More importantly, the Property

Browser eliminates repetitive editing of your tool path by allowing you to

select and change any number of conditions for any number of cutting

operations in one simple step. For example, change the stock allowance on

three separate pockets and one contour in a single easy step.

|

| |

- Property Browser providing extensive

control over all cutting conditions

|

|

KBM Process Manager...

Multiple machining cycles applied to

multiple part features in one step.

A process is any number of machining cycles combined

together. For example, a standard process for creating a pocket might be:

rough the pocket with a concentric climb cut, change the tool, finish cut

the walls using a contouring cycle, and lastly finish cut the bottom of

the pocket using a zigzag style pocket cycle. Processes are saved in the

Process Manager database for future use, where they can be easily applied

to any number of features on any part.

|

| |

- Process Manager to machine one or more

part features with one or more machining cycle(s) in one simple step.

|

|

Universal Post Processing...

G-Code for virtually any CNC machine.

ESPRIT will output G-code for virtually any CNC

machine thanks to its Universal Post Processing system. ESPRIT’s

extensive post processor library contains posts for a large number of the

more popular machine tools and the entire library is available to you on

the product CD. You also have the power of the post processor generator

to create a new post from scratch or just as easily modify one of the

existing posts from the library to suit your individual preferences. In

either case you have complete control over the format of your G-code, and

you have the ability to create an unlimited number of post processors.

|

| |

- Universal post processing with an

extensive library and custom post generator

|

|

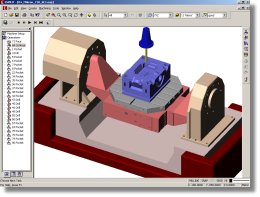

Simulation and Verification...

Assures your NC programs are of the highest

quality.

ESPRIT’s Solid Simulation and Verification assures

your NC programs are of the absolute highest quality by simulating the

machining cycles along with the entire machining environment, including

stock material, fixtures and clamps, in dynamic solid shaded graphics.

Using ESPRIT’s built-in part inspection tool you can easily compare the

original “as-designed” part to your “as-machined” work piece to assure

part accuracy. The realistic images let you see the part as if you were

holding it in your hand.

|

|

- Solid simulation and verification with

comprehensive collision detection

|

ESPRIT is packed

with power to handle the most complex production work,

yet easy to use for the quick programming of simple jobs. Tombstone set-ups

with multiple parts, hundreds of machining cycles, and 10-25-50 or more

tools are routine with ESPRIT. The programming of 2 ˝-axis parts, 5-axis

index machines, and 3D surface/solid machining is available together within

the same familiar and comfortable Windows interface.

ESPRIT is packed

with power to handle the most complex production work,

yet easy to use for the quick programming of simple jobs. Tombstone set-ups

with multiple parts, hundreds of machining cycles, and 10-25-50 or more

tools are routine with ESPRIT. The programming of 2 ˝-axis parts, 5-axis

index machines, and 3D surface/solid machining is available together within

the same familiar and comfortable Windows interface. ![]()